With the new “iControl” process monitoring system, WFL gives the future machine operator a whole bundle of functions to ensure reliable and economical production, particularly in series production. On the one hand, the machine and tools should be used with maximum productivity; on the other hand, the process should run as stably and reliably as possible. The software package that WFL provides for this is extremely diverse and offers a suitable monitoring tool for practically every processing situation.

Category: Uncategorised

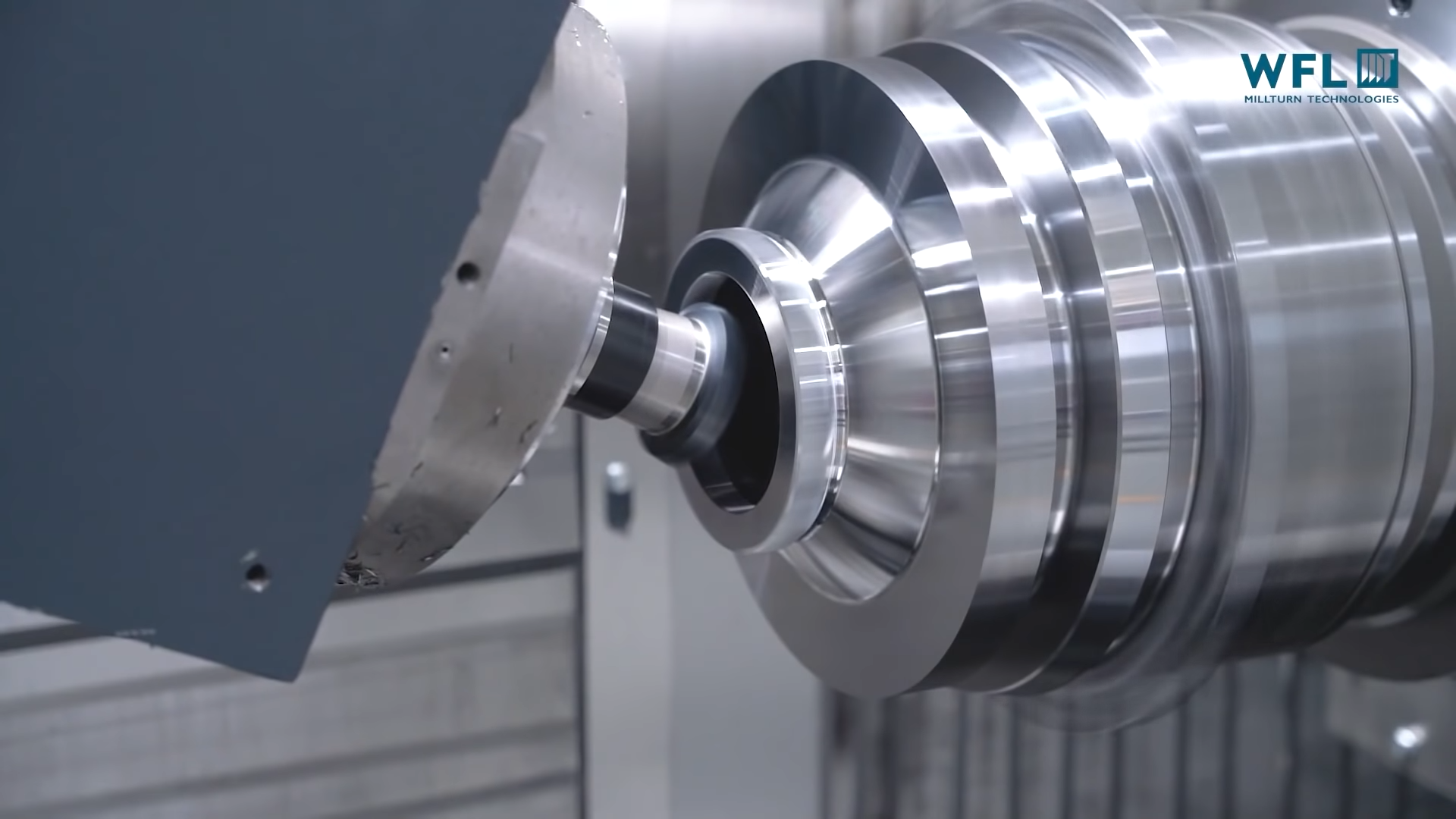

The MILLTURN performance makes it possible

At EMO Milan WFL was presenting the new M20 MILLTURN complete machining center for the first time. The most ground-breaking aspect, however, is the machine’s new design. The continuous toughened-glass front features an integrated performance data display and a touch panel for conveniently operating the tool magazine from the front of the machine.

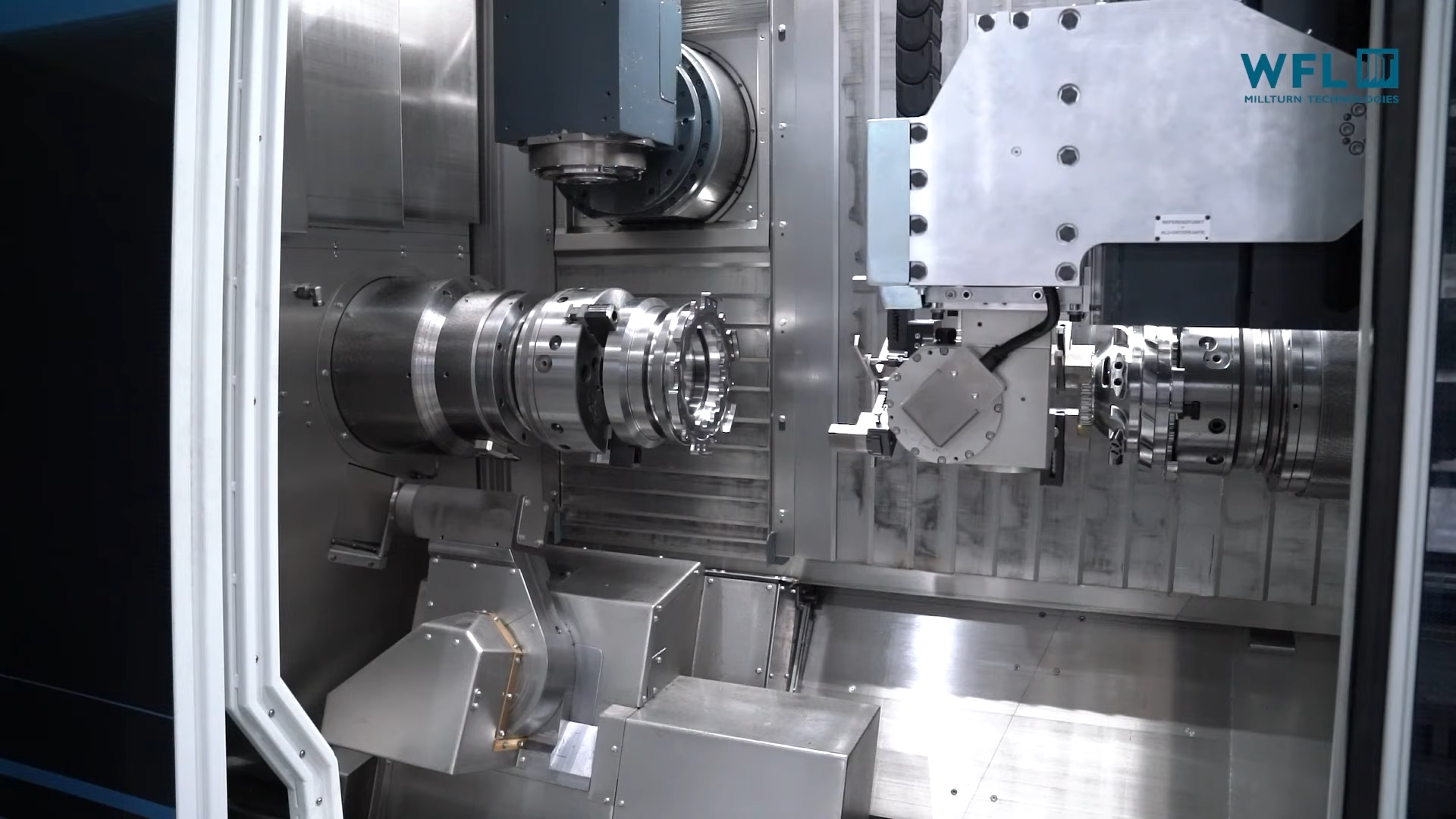

Universal machining solutions are also possible with the new generation of the M50-G MILLTURN, with greater axis distance and improved performance. The optional centre distance of 6000mm enables efficient machining of long shaft parts. The machine’s existing potential is fully utilised, particularly in terms of the increased drive power, combined with the HSK-A100 or Capto C8 tool accommodation. A separate pick-up magazine is also available for very long and/or heavy tools. Workpieces with a length of 1600mm can be automatically inserted and changed.

The new M20 MILLTURN from WFL

The M20 MILLTURN has been celebrating its world première at EMO in October 2021. The aim when developing the M20 was to introduce a particularly robust machine with the highest possible long-term accuracy. The machine frame is made from spheroidal graphite iron, ensuring optimal stability plus outstanding damping properties. This also means heavy roughing cuts can be made without compromise. The most ground-breaking aspect, however, is the machine’s new design. The continuous toughened-glass front features an integrated performance data display and a touch panel for conveniently operating the tool magazine from the front of the machine.

WFL’s new M20 -G – Clamp Once

MTDCNC caught up with Simon Pollard from Kyal Machine Tools at EMO Milan 2021 on WFL’s stand. Simon explains that their new M20 launch gives their customers a complete Millturn solution with added benefits like automation and a bottom spindle. The M20 is WFL’s latest concept in ‘smart’ machining which includes new software.

Kyal Machine Tools continues to invest

At EMO 2021 in Milan MTDCNC caught up with Simon Pollard (Managing Director of Kyal Machine Tools) to not only discuss a new launch machine from WFL but also of the investment in Steve Malone joining the company as their UK Sales Manager. Steve brings a wealth of experience to Kyal Machine Tools within the machine tool and automation sectors. Also watch out for their new website launching before the end of this year.

WFL launch new innovations at EMO 2019

Kyal Machines Tools have been representing WFL Millturn Technologies for many years in the UK, Simon Pollard talks to MTDCNC about the new options available like the new iControl, Industry 4.0 software options and the intelligent boring bar system which have been launched at EMO 2019. Simon mentions about the partnership with their customer which is key and many ft he new options from WFL have been lead by the demands of their customers to keep one step ahead of their industry market.

Weiler lathes go bigger at EMO 2019

Simon Pollard (Managing Director of Kyal Machine Tools) explains to MTDCNC about their relationship with Weiler and how a number of their UK clients have helped Weiler create bigger and better options as some clients have needed a larger working area but Weiler have made the V90 to hold the same tight tolerance as their smaller lathes. Kyal’s relationship with the likes of the Oil and Gas sector have helped develop the V90 lathe and this is a perfect example why Kyal Machine Tools is not only supplying new options but also working as a partner rather than just supplying off the shelf lathe.

What makes Weiler lathes the best in the market

MTDCNC speaks to Walter Nirschl at the WFL technology days about the partnership they have and also why Weiler lathes are so good. Walter also explains that they have made some positive improvements like the new control system. The machines are constantly improved by listening to their customers feedback, for example having larger spindles offering larger spindle bores which enable clamping from both sides and the machines are well known for being very rigid and very precise. Weiler machines are sold in the UK by Kyal Machine Tools, so if you are looking for a high end lathe, get in touch.

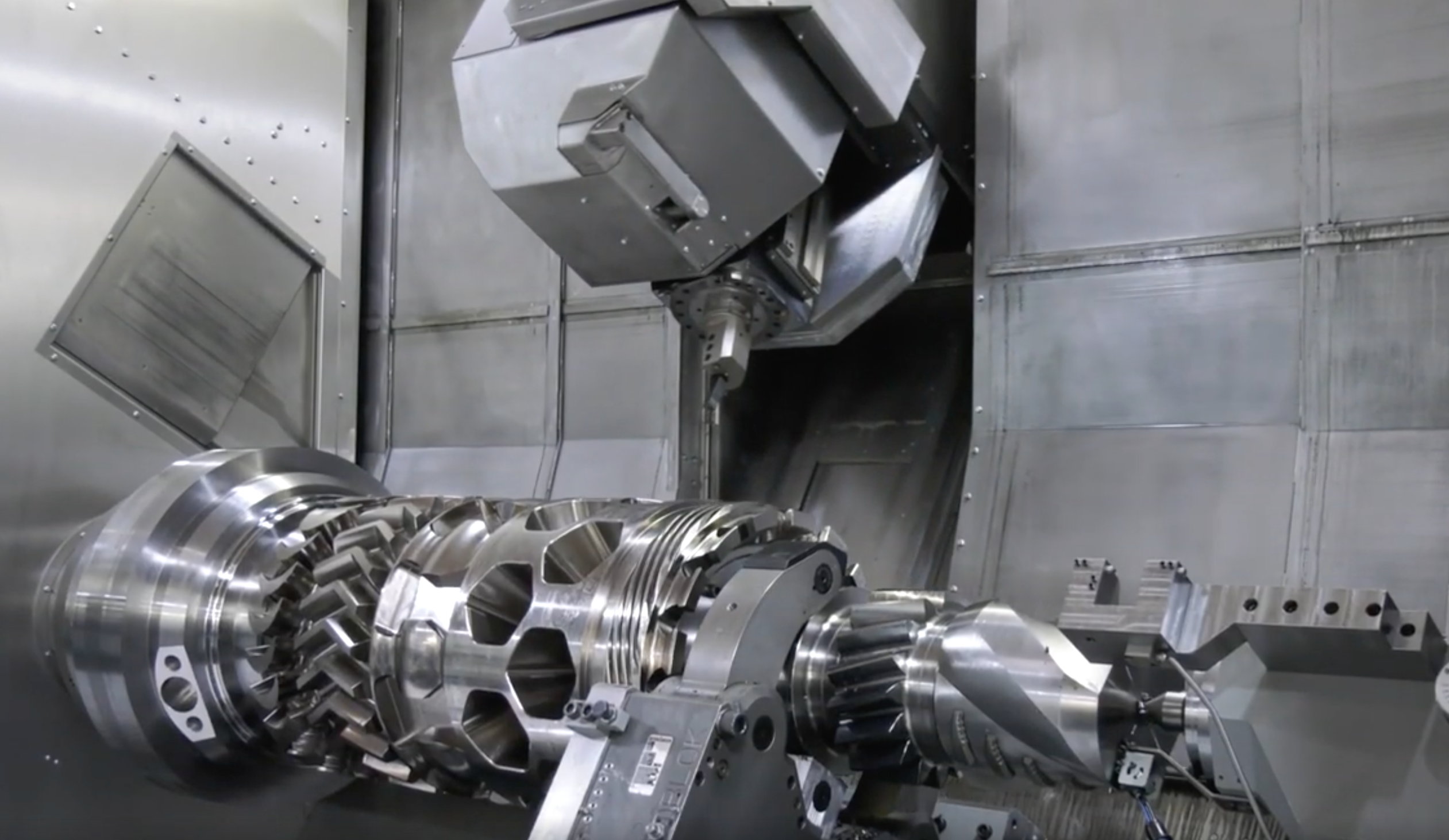

WFL technologies for the plastics industry

Complex geometries and difficult materials are the typical challenges for the machining of components for plastic machinery. Time-saving programming solutions combined with precise milling, turning and drilling enable highly efficient production of any kind of complex shaft- and chucking parts. WFL offers the possibility of simple parameter programming of screws. These programs can be directly simulated in the programming editor. Even programs for complex screws can be generated efficiently. Thanks to the broad technological spectrum of a MILLTURN and the decades of experience in the plastics industry, customers can achieve ultimate levels of productivity.

Decisive Tooling Solutions by WFL

For the first time, WFL Tooling Solutions presented their innovative tools, which guarantee improved accessibility and an outstanding level of flexibility when used on complex workpiece geometries. Sensor technology is of particular importance in order to ensure optimum protection of the machine, tool and workpiece. Thanks to these tools, the machine is able to identify load peaks and respond to them in real time. WFL is setting new standards in measurement technology too. A profile can be scanned in high resolution with the help of the scanning measuring probe, without the workpiece having to be unclamped from the machine.