MTDCNC speaks to Walter Nirschl at the WFL technology days about the partnership they have and also why Weiler lathes are so good. Walter also explains that they have made some positive improvements like the new control system. The machines are constantly improved by listening to their customers feedback, for example having larger spindles offering larger spindle bores which enable clamping from both sides and the machines are well known for being very rigid and very precise. Weiler machines are sold in the UK by Kyal Machine Tools, so if you are looking for a high end lathe, get in touch.

Month: May 2019

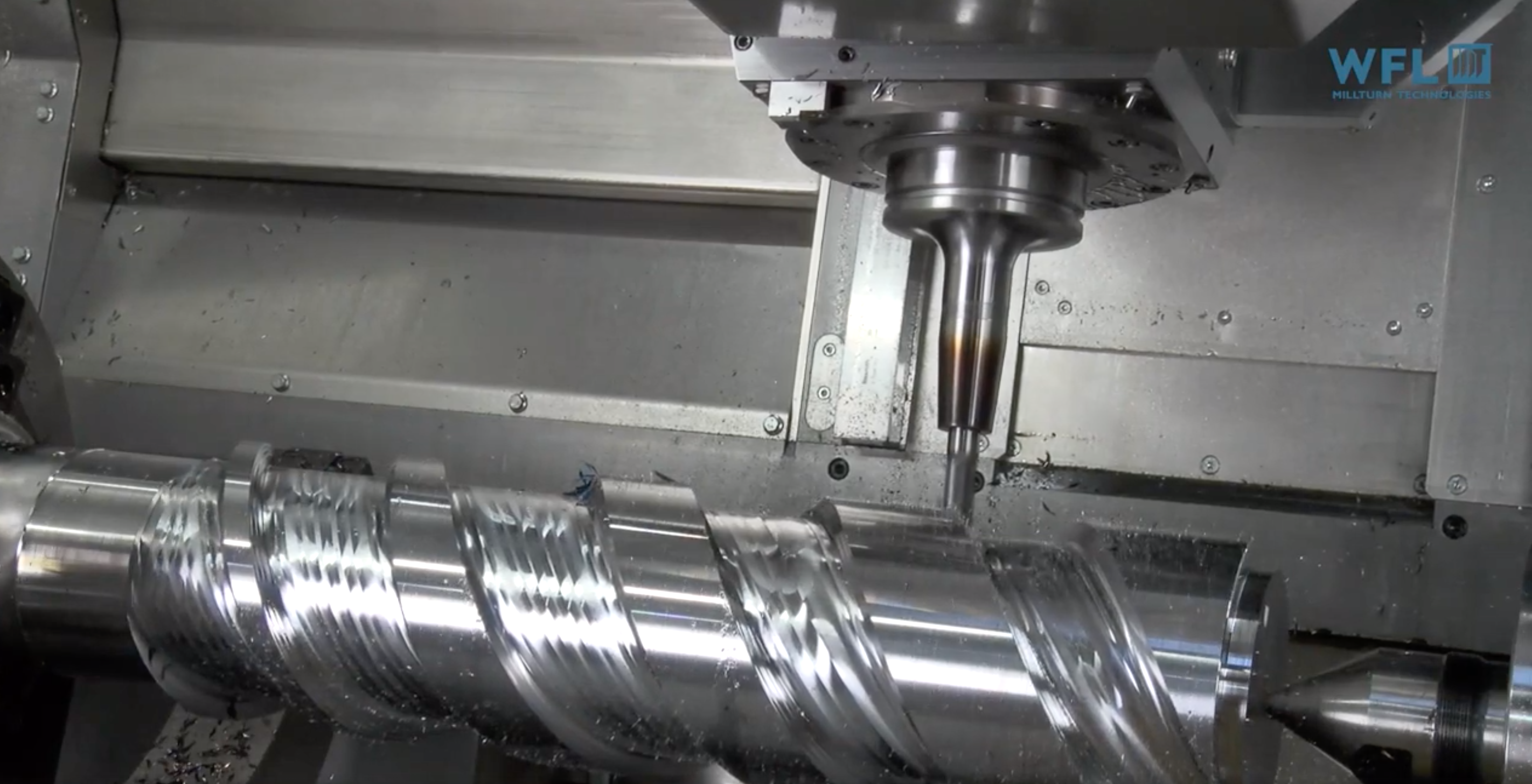

WFL technologies for the plastics industry

Complex geometries and difficult materials are the typical challenges for the machining of components for plastic machinery. Time-saving programming solutions combined with precise milling, turning and drilling enable highly efficient production of any kind of complex shaft- and chucking parts. WFL offers the possibility of simple parameter programming of screws. These programs can be directly simulated in the programming editor. Even programs for complex screws can be generated efficiently. Thanks to the broad technological spectrum of a MILLTURN and the decades of experience in the plastics industry, customers can achieve ultimate levels of productivity.

Decisive Tooling Solutions by WFL

For the first time, WFL Tooling Solutions presented their innovative tools, which guarantee improved accessibility and an outstanding level of flexibility when used on complex workpiece geometries. Sensor technology is of particular importance in order to ensure optimum protection of the machine, tool and workpiece. Thanks to these tools, the machine is able to identify load peaks and respond to them in real time. WFL is setting new standards in measurement technology too. A profile can be scanned in high resolution with the help of the scanning measuring probe, without the workpiece having to be unclamped from the machine.

WFL provides first-class software solutions

At WFL Millturn Technologies there are also software innovations to behold. CrashGuard Studio is a 3D simulation software that enables users to perform programming on a PC for the preliminary verification of NC programmes. The benefits include the visualisation of all programming steps to detect errors at an early stage, the improved quality of the NC programmes in terms of efficiency and machine safety, and the reduced set-up times on the machine thanks to the preliminary simulation. This provides the machine operator with a finished programme that has already been tested for crashes.