At WFL Millturn Technologies there are also software innovations to behold. CrashGuard Studio is a 3D simulation software that enables users to perform programming on a PC for the preliminary verification of NC programmes. The benefits include the visualisation of all programming steps to detect errors at an early stage, the improved quality of the NC programmes in terms of efficiency and machine safety, and the reduced set-up times on the machine thanks to the preliminary simulation. This provides the machine operator with a finished programme that has already been tested for crashes.

Category: Uncategorised

WFL now offers automation solutions with FRAI

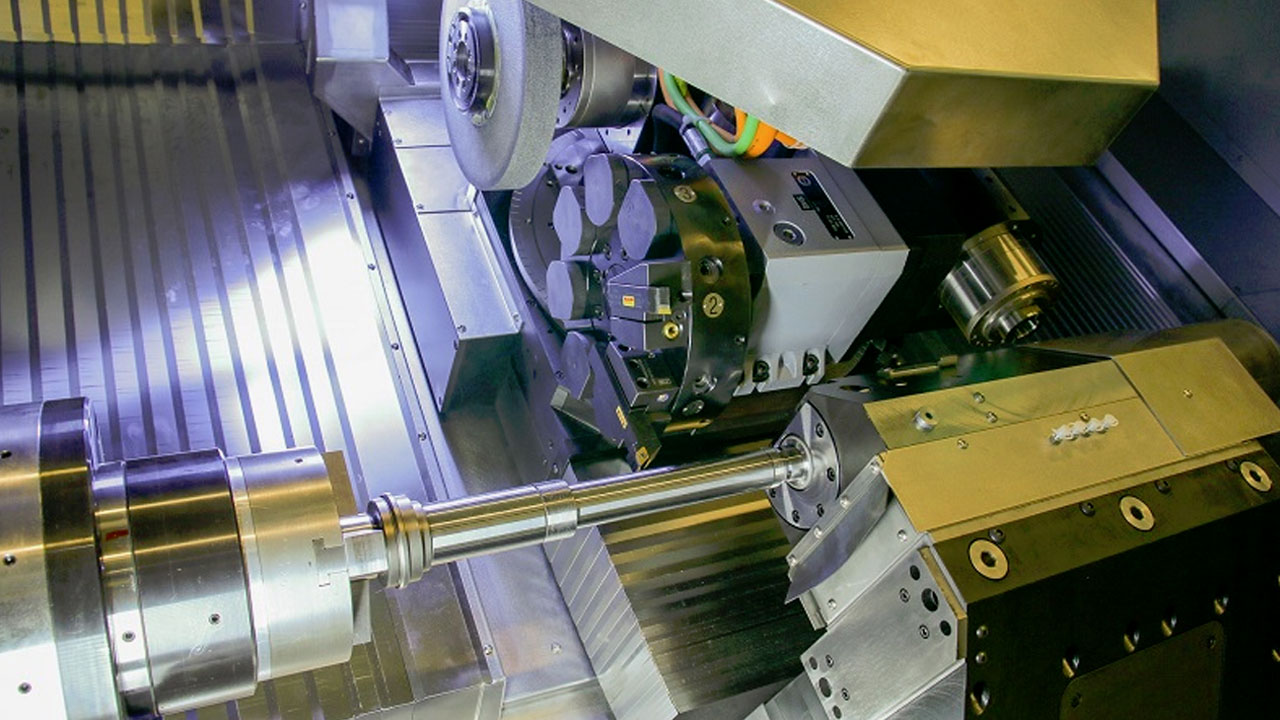

WFL Millturn Technologies has always been involved in the area of automation. From articulated robots to gantry loaders, all systems that are combined with a MILLTURN bring an element of high-tech and a breath of fresh air into the automation of WFL’s machinery.

High-tech automation solutions

WFL Millturn Technologies has always been involved in the area of automation. From articulated robots to gantry loaders, all systems that are combined with a MILLTURN bring an element of high-tech and a breath of fresh air into the automation of WFL’s machinery. The acquisition of FRAI Elektromaschinenbau GmbH represents another step towards innovation in complete machining, paving the way for a digital future.

Automated and flexible systems are playing an increasingly significant role in the production of workpieces. Automation solutions are in high demand, particularly for smaller machine series, as the machine times are short and the batch sizes high. Unattended production methods have long been used by automotive manufacturers, the aerospace industry and, above all, mould construction companies to produce equipment for machine tools. Other sectors with less of a focus on automation are nonetheless showing increased interest in this area, above all due to the possibility of introducing unattended night and weekend shifts.

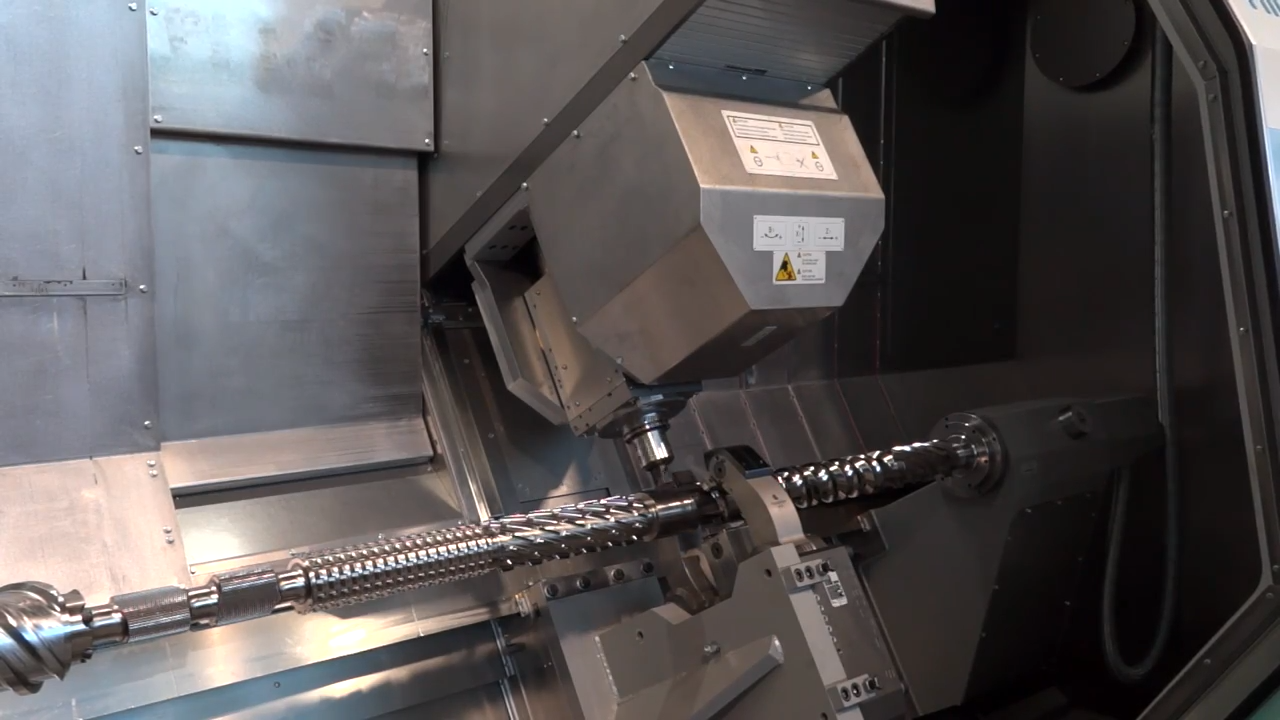

WFL Millturn Technologies works with different automation variants for automated workpiece loading and unloading, depending on each customer’s requirements. The series ranges from bar feeders to gantry loaders through to articulated robots. Peripheral transport and storage systems for workpieces, tools and clamping devices can be combined as desired.

This brings some key advantages for the user, such as continuous productivity with minimal operating effort. Automated machines are also ideally suited to repetitive tasks. However, robots are not only used in large-scale series production; there are also many advantages to automation for small batch sizes, when used in combination with easy-to-program software.

Customer-specific options, such as unloading samples, inscribing, cleaning, measuring blank parts, or even additional processing tasks performed by the robot like deburring, provide optimal conditions for automation.

Symbiosis with FRAI Elektromaschinenbau GmbH

WFL Millturn Technologies and FRAI Elektromaschinenbau GmbH have enjoyed a reliable partnership for some time now, when it comes to implementing automation projects.

With WFL Millturn Technologies having acquired 100% of FRAI Elektromaschinen GmbH in October, their automation expertise will only be enhanced. Individual automation solutions are a significant factor for WFL’s future success. The integration of FRAI therefore represents the perfect addition to WFL’s existing range of production solutions.

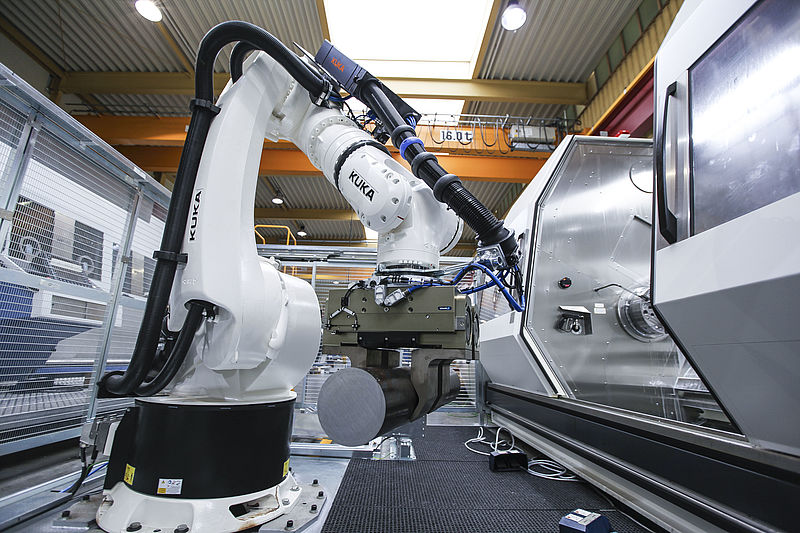

Industry robots for M65 MILLTURN

One successful project implementation involved a FRAI robot automation system with a KUKA robot (KR 510), which is suitable for automating a M65/4500 MILLTURN.

Shaft components of various geometries are automatically removed from workpiece pallets and inserted into the CNC machine’s clamping device for machining. The machined parts are then placed on the pallet system.

The jaws have a gripping range of a 75–190 mm workpiece diameter, which covers the diameter for all blank and finished parts in the entire parts range.

Robot cells for M30-G MILLTURN

One of the automation projects in progress at WFL involves a robot cell with transport trolley pick-up/drop-off spaces and gripper exchange system for a M30-G MILLTURN.

An automatic gripper exchange system with two different gripping heads for shaft components is in the pipeline. Two individually-controlled parallel grippers are built next to each other here, so that the components can be picked up in two gripping positions. The parallel grippers feature jaws mounted on a (tool-free) fast adjustment system. The grippers cover all blank and finished part diameters.

Work on the chuck parts is performed according to the double gripper principle, i.e. the two front grippers can be equipped differently (blank/finished part). The intention is to use jaws with plastic inserts for the chuck part gripper to avoid damage being caused to the aluminium part.

A KUKA robot is used for this machine (KR Quantec extra, nominal load capacity 120 kg, nominal working radius 2896 mm).

Innovative and functional

WFL’s product portfolio now offers the ideal combination of highly productive machine and production solutions and integrated automation solutions.

New visitor record at the Technology Meeting 2019

At this year’s technology meeting, WFL Millturn Technologies set a new visitor record. On 4,000 m2 of exhibition space, live cutting on all machine types and the latest automation and software solutions were shown. Fascinating evening events at the Ars Electronica Center Linz and the Stadlerhof Wilhering provided a perfect setting for the trade fair program.

Compared to the Technology Meeting 2017, the number of visitors to this year’s in-house exhibition rose by almost 20 percent – a great result for the machine tool manufacturer in Linz. Most of the guests travelled from Austria, Germany and the neighbouring countries. Chinese, American, Brazilian and Arabian trade fair participants mainly took up wide travel routes.

Above all, the visitors were enthusiastic about the variety of editing options offered by WFL. Customers can rely on the high-quality technical and technological expertise of WFL employees, especially for complex work pieces. Manufacturers from a wide variety of industries travelled from near and far to discuss the optimum technical possibilities for their production tasks at WFL. Especially in the fields of measurement technology, digitization and automation, visitors showed great interest in the future of machining technologies.

A wide range was presented not only during the day, also the evening program had a lot to offer. On Tuesday, under the motto “Tech Night” at the Ars Electronica Center in Linz, a guided tour through the museum and an impressive space show in Deep Space were organized. At a dinner on the top floor and pleasant jazz music, the guests could enjoy the view of the Danube and the beautifully lit Linz. The second evening was traditionally celebrated under the title “Austrian Night” in a square courtyard in Wilhering. In addition to an interesting quiz, great winner prizes and atmospheric music, the guests could experience a unique evening with classic Austrian delicacies.

We are already looking forward to the next WFL Technology Meeting 2021!

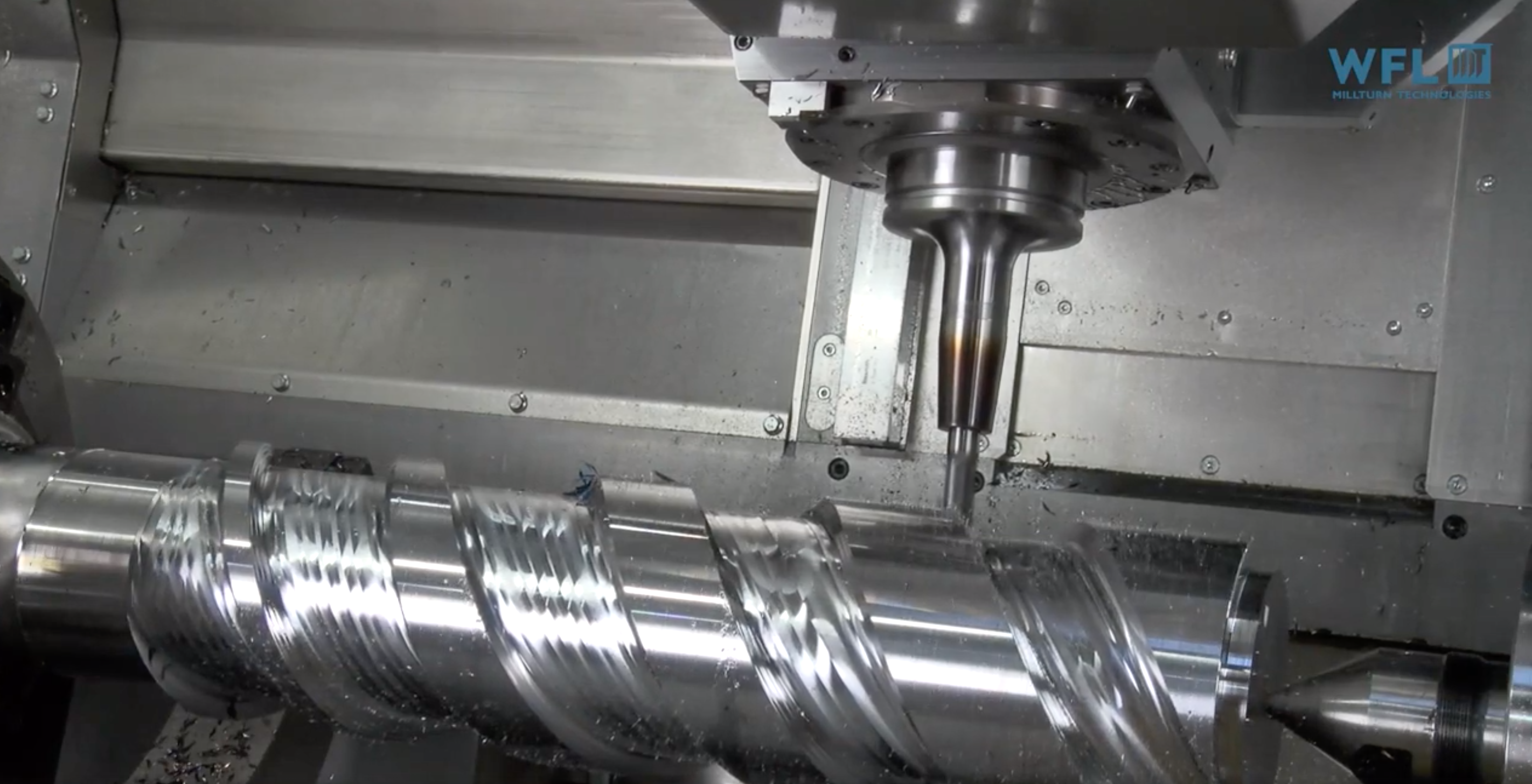

M80X MILLTURN / 3000mm by WFL Millturn Technologies

At this year’s WFL Technology Meeting, WFL Millturn Technologies was setting a new visitor record. On 4,000 m2 of exhibition space, live cutting on all machine types and the latest automation and software solutions were shown. Applications from the aviation industry, the plastics industry and high-tech mechanical engineering were the primary sectors covered. Highly efficient automation solutions, the latest technologies and practical specialist presentations were also on top of the agenda.

WFL Millturn Technologies is acquiring FRAI Elektromaschinenbau GmbH

October 2018: Linz, Austria – WFL is acquiring FRAI Elektromaschinenbau GmbH. FRAI, founded in 1984, and focusing on automation solutions in the machine tool industry, is passing with 100% to WFL Millturn Technologies. CEO and founder, Aitzetmüller Friedrich, will go into retirement after am agreed transition period. He was searching for a succession for his company and found it in WFL Millturn Technologies.

WFL Millturn Technologies, the in Linz based manufacturer of multifunctional complete machining centers, is acquiring company FRAI Elektromaschinen with October with 100%.

The perfect symbiosis of highly productive machinery and manufacturing solutions combined with automation solutions will reform the WFL product portfolio from now on. The company FRAI Elektromaschinenbau Gesellschaft m.b.H, located in St. Konrad (about 50km away from Linz) will be taken over by WFL Millturn Technologies GmbH & Co. KG by 100%. There will be a complete takeover of the trade name, the established customers, the reference projects, the production capacity and also its professional staff. The office and production site will remain in St. Konrad. Mr. Aitzetmüller, CEO and founder of FRAI will direct the operational management for a defined time period to ensure a smooth integration.

Automation solutions have been and are still a constant companion when it comes to a purchasing decision of a MILLTURN. Especially with the smaller sized MILLTURN series automation becomes essential. Also the topic digitalization demands an increasing offer of automation solutions. “Automation solutions have a high importance to many of our customers or are in several cases a prerequisite for an order. With the takeover of FRAI Elektromaschinenbau GmbH we see the ideal opportunity for this solution“, so Mr. Jungreithmayr, CEO of WFL Millturn Technologies. WFL Millturn Technologies and FRAI Elektromaschinenbau GmbH are already connected through a long-standing partnership in the area of automation solutions.

„We are very pleased to have FRAI as the perfect addition to our existing manufacturing solutions and see this expansion of our automation competence and individual automation solutions as significant success factor”, Mr. Norbert Jungreithmayr, CEO WFL.

WFL Millturn Technologies proves to be leader in technologies

Stefan Haas (Regional Sales Manager) takes Mark on a tour of their stand at AMB 2018 WFL presents its progress by dealing with different topics concerning Industry 4.0, such as the new WFL DATA ANALYZER or the brand new version of CrashGuard Studio. The actual highlight of the show is the presentation of the new M50 MILLTURN with a bigger centre distance and increased performance as well as an option for a counter spindle version.

Discover the new MikroTurnGrind 1000

The MikroTurnGrind 1000 is a brand new development that combines the advantages of high precision hard turning and grinding in a single machine. This machine has been developed to meet the demand from manufacturers read more

NEW: The Mikroturn® 100 XLD

The Mikroturn 100 XLD, (XLD stands for extra large diameter) is a modified version of the Mikroturn 100. The Mikroturn 100 XLD has a turning diameter of up to Ø 610 mm instead of Ø 380 mm for the standard Mikroturn 100. Despite a small machine floor surface of only read more

Automated finish hard turning replaces grinding

Hembrug supplies a German manufacturer of drive shafts for hydraulic pumps with a fully automated high-precision hard turning process with an integrated grinding operation. The manufacturer has a large spectrum of products and was looking for a more flexible process for an older grinding machine. Read more

Where else to meet us in 2018?

Also this year Hembrug is taking part in a large number of international trade fairs. We have already participated in the Grindtec in Augsburg, the MACH in England and the CCMT in Shanghai. Want to know more about our latest developments and meet us in person? Visit us at one of the exhibitions below. We very much look forward meeting you!

IMTS, Chicago

10-09/15-09-2018

View details

AMB, Stuttgart

18-09/22-09-2018

View details

BIMU, Milan

09-10/13-10-2018

Hall 9, Booth C132-D197

Precision Fair, Veldhoven, the Netherlands

14-11/15-11-2018

Booth nr. 105

WFL’s World Premier launch of the M30-G Millturn

Simon Pollard (MD of Kyal Machine Tools – UK distributors of WFL machines) explains to MTDCNC about the launch of the new M30-G Millturn. The M30-G is a entry level machine to help reduce delivery lead times but also offering a great competitive price for an entry level WFL Millturn. Simon explains that their are 3 versions of the machines and also talks about the benefits to the customer. Watch this video to find out more…

A World Record from WFL and Sandvik

Stefan Haas discusses the partnership between WFL and Sandvik to fit a boring bar which is 18xD the diameter giving it World Record status. This offers such great advantages as the boring bar is loaded with special sensors giving unique information to the customer and offer unbeatable performance. Talk to Kyal Machine Tools who represent WFL in the UK for further information.